October 21, 2022

99 Problems But A Valve’s Not One: How To Optimize Critical Valve Inspection

Properly maintained and functioning valve and Emergency Shut Down (ESD) systems are key to ensuring the safe operation of pipeline networks. To maintain a safe working environment and meet regulations, it is crucial to know where these valves are, what their maintenance history is, and what is their current operational status. Managing this data manually can be difficult and error prone.

In 2020 Cenozon was engaged by a Midstream Operator to assist them with their Critical Valve inventory. What began as an inventory evolved into the start of a Risk Based Inspection (RBI) program that has allowed this organization to exceed their regulatory requirements year after year. Not only do they have a proven track record (and easily accessibly records to prove it), but they are also increasing their inspection intervals, saving valuable work-hours and resources. All these improvements are possible while still having reliable data, ensuring that the integrity of their system is intact.

That system that began as a one-off program for a client has been developed into a full-fledged toolbox for managing ESD & Valve assets, built on Cenozon’s industry-proven FIND platform.

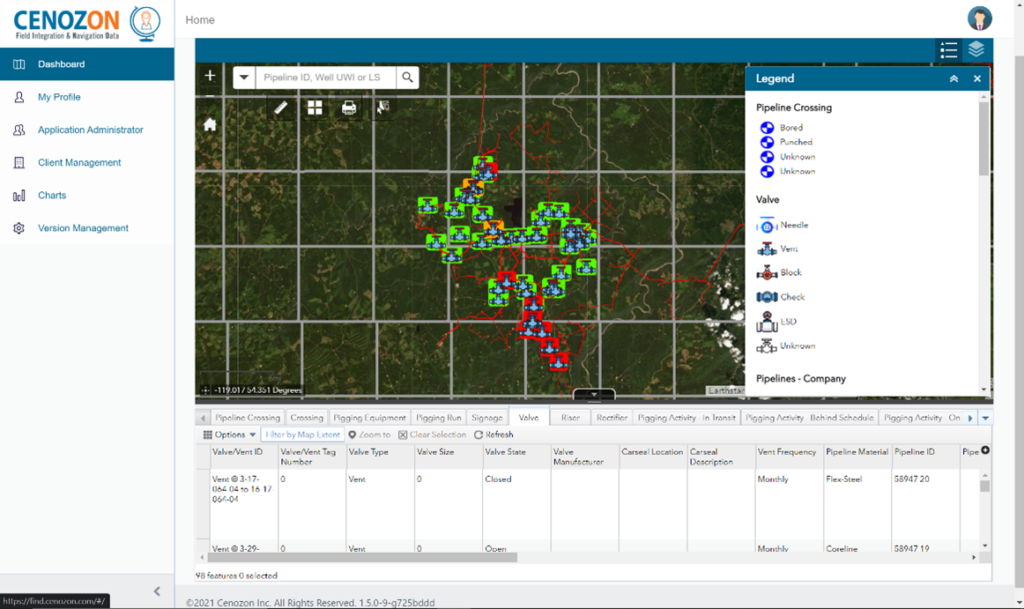

FIND features a map-based platform that associates each asset with its geographic location and corresponding pipeline network – including any parent or child assets within the operational hierarchy. Maintenance records are automatically associated with the corresponding asset, and can be analyzed, updated, and shared with other stakeholders or service providers.

The application also features a mobile app component, designed for field-workers and service providers to complete forms directly in the application, and automatically capturing GPS location, time, date, and personal information.

Scheduling tools are built in, allowing for inspection, repair or monitoring, and activities can be assigned to the proper employee. An automated notification system can help to ensure maintenance is performed regularly and equipment remains in working order.

Regulatory tools are built-in to assist various tasks, such as record-keeping, reporting, auditing, failure investigation and preventative maintenance planning. These tools can simplify regulatory compliance, saving working-hours and headaches. Analytics tools are built-in as well, such as customizable dashboards, KPIs, and scheduling optimization – to help you understand your operations and optimize productivity.

To learn more about Cenozon’s FIND, visit https://www.cenozon.com/solutions/pipeline-integrity/find/